Erik Teuber

Erik Teuber, M.Eng., M. Eng.

Project description

Former project: Development of a liquid cell for transmission electron microscopy of nanostructures in aqueous and non-aqueous solution

Project area: A2

Supervisors: Prof. Dr. rer. nat. habil. Lothar Frey, Dr.-Ing. Michael Jank, Prof. Dr. rer. nat. habil. Erdmann Spiecker

Liquid cell transmission electron microscopy (LCTEM) is a novel technique that enables investigations into nanostructures in liquid environment in situ excluding desiccation effects [1-3]. The nanoparticle dispersion is encapsulated between two electron transparent membranes to prevent vaporization of the specimen in the ultra-high vacuum of an electron microscope. The fabrication of these liquid cells is conducted using conventional semiconductor technology as well as bulk micromachining processes.

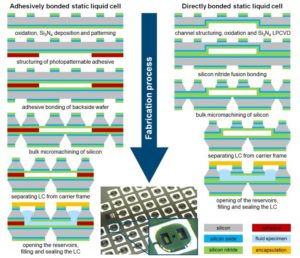

In this project an adhesively bonded static liquid cell was developed. For this purpose, two silicon nitride coated, structured silicon substrates are bonded to each other using a photo patternable adhesive, i.e. SU-8 (Figure 1). The fabrication process allows for tailoring the liquid cell design to particular experiments. In our case the layout is adapted for the application with conventional TEM specimen holders (cf. Figure 1).

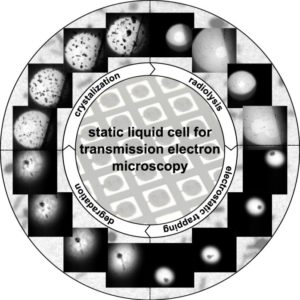

To achieve this, a process optimization was conducted to get liquid cells with a circular shape with 3 mm in diameter. A predetermined breaking point of a cantilever fixating the liquid cells to the carrier frame during the fabrication process was developed for prevention of a silicon protrusion at the cell rim. In cooperation with A. Hutzler (Project A2) liquid cell in situ TEM experiments were conducted for the first time at the Erlangen facilities. Typical LCTEM phenomena like Brownian motion, radiolysis induced bubble formation, electrostatic trapping as well as crystallization and degradation processes of nanostructures could be observed (Figure 2).

Fig. 1: Process schematics for fabrication of adhesively and directly bonded static liquid cells.

Fig. 2: Different phenomena observed with the in house fabricated static liquid cell.

References

[1] N. de Jonge and F. M. Ross, Nat. Nanotechnol. 6 (2011) 695.

[2] N. de Jonge et al., Adv. Imag. Elect. Phys. 186 (2014) 1.

[3] H. Zheng et al., MRS Bulletin 40 (2015) 12.